-

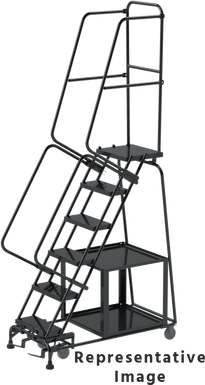

Stock Picking Ladders, 7 Step, 32 in Wide Base, 21 in Deep Top Step, Serrated Tread, Setup

Stock Picking Ladders, 7 Step, 32 in Wide Base, 21 in Deep Top Step, Serrated Tread, Setup

$1,597.00Model #: SPL-7-G-SU -

Stock Picking Ladders, CALOSHA, 7 Step, 24 in Wide Base, 21 in Deep Top Step, Serrated Tread, Setup

Stock Picking Ladders, CALOSHA, 7 Step, 24 in Wide Base, 21 in Deep Top Step, Serrated Tread, Setup

$1,602.00Model #: CAL-SPL-7-N-G-SU -

Stock Picking Ladders, CALOSHA, 9 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread, Setup

Stock Picking Ladders, CALOSHA, 9 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread, Setup

$1,605.00Model #: CAL-SPL-9-14-R-SU -

Stock Picking Ladders, CALOSHA, 9 Step, 32 in Wide Base, 14 in Deep Top Step, Expanded Metal Tread, Setup

Stock Picking Ladders, CALOSHA, 9 Step, 32 in Wide Base, 14 in Deep Top Step, Expanded Metal Tread, Setup

$1,605.00Model #: CAL-SPL-9-14-X-SU -

Stock Picking Ladders, 10 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread, Setup

Stock Picking Ladders, 10 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread, Setup

$1,611.00Model #: SPL-10-14-R-SU -

Stock Picking Ladders, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread

Stock Picking Ladders, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread

$1,621.17Model #: SPL-11-P -

Stock Picking Ladders, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread, Setup

Stock Picking Ladders, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread, Setup

$1,621.17Model #: SPL-11-P-SU -

Stock Picking Ladders, CALOSHA, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread

Stock Picking Ladders, CALOSHA, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread

$1,621.17Model #: CAL-SPL-11-P -

Stock Picking Ladders, CALOSHA, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread, Setup

Stock Picking Ladders, CALOSHA, 11 Step, 32 in Wide Base, 21 in Deep Top Step, Perforated Tread, Setup

$1,621.17Model #: CAL-SPL-11-P-SU -

Stock Picking Ladders, 11 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread

Stock Picking Ladders, 11 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread

$1,628.63Model #: SPL-11-14-R -

Stock Picking Ladders, 11 Step, 32 in Wide Base, 14 in Deep Top Step, Expanded Metal Tread

Stock Picking Ladders, 11 Step, 32 in Wide Base, 14 in Deep Top Step, Expanded Metal Tread

$1,628.63Model #: SPL-11-14-X -

Stock Picking Ladders, CALOSHA, 11 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread

Stock Picking Ladders, CALOSHA, 11 Step, 32 in Wide Base, 14 in Deep Top Step, Abrasive Mat Tread

$1,628.63Model #: CAL-SPL-11-14-R

Showing 12 of 334 items